Disposable Degradable Plastic Lunch Box Food Plate Tray Making Machine

Disposable degradable lunch box machine also named disposable food plate making machine, is the latest core product developed by our company, integrated, punching, cutting, and stacking. Meanwhile our machine has a wide range of uses and is suitable for most customers’ requirements. this equipment can produce bowls, plates, various fast food boxes, packing boxes, supermarket trays, moon cake boxes, tofu boxes, biscuit boxes, etc. Stable operation, low noise, high efficiency and good quality.

Table of Contents

Advantages of degradable food box machine

Raw material of degrable lunch food box

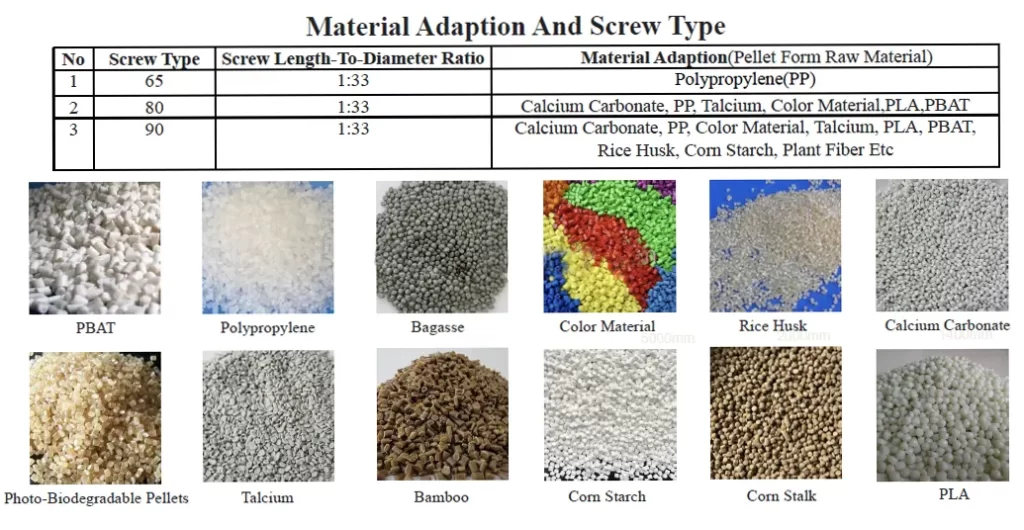

Disposable degradable lunch box machine can adopt the following materials: Calcium Carbonate, PP, Color Material, Talcium, PLA, PBAT, Rice Husk, Corn Starch, Plant Fiber Etc

Degradable Products Show

The degradable plastic food box machine is capable of producing a wide variety of food packaging tableware. By combining different raw materials, the machine can manufacture a diverse range of products, including PLA food boxes, corn starch trays, PBAT containers, and more. The flexibility of this equipment allows for the creation of various eco-friendly and biodegradable options to meet different packaging needs.

DY90B automatic degradable food box machine specification

DY-90B Specification | |||

Rated Power | 115kw | Workshop Requirement | 150m2 |

Power Consumption | 35kwh | Machine Size | 7000mm*1400mm*2000mm |

Labor Usage | 2/Shift | Weight | 5.5T |

Machine Line Composition | DY90B Sheet Extruder, Forming Machine, Fully Automatic Punching Machine, Mixer, Side Material Smash Machine, One Set Of Customized Mold, Fully Automatic Punching Knife | ||

Forming Machine | |

Maximum Shaping Area | 850mm×300mm |

Maximum Shaping Depth | 80mm |

Cooling Method | Fan Cooling |

Output Capacity | 20-45 mold/min |

Controller | PLC |

Power of Shaping Section | 1.5kw |

if you are interested in foam box machine, you can hit link – ps foam box forming machine – to learn more