EPE FOAM SHEET EXTRUSION MACHINE

What is the EPE foam film extrusion machine?

Table of Contents

Polythene foam sheet machine can make different foam sheet widths and thicknesses according to customer requirements. Additionally, it has the capability to produce foam pipes, foam net, foam rods, foam profiles, and more by simply changing the mold and machine parts.

The foam sheet boasts various features, including dampproof, shockproof, soundproof, heat preservation, and good plasticity. Moreover, after laminating, the foam sheet attains high dampproof performance, making it ideal for placement under the floor.

What features does the epe foam sheet extrusion machine have?

EPE foam film making machine producing fine closed cell Polyethylene foam sheet, by our unique designed Screw and Barrel system, using Butane foaming agent, Talc powder or Talc masterbatch and Anti-shrinking agent (GMS for short-Surface Active Agent) by accumulated experience and advanced technology.

- PE foam and related products originate from PE resin, and manufacturers expand and shape them by heating and extruding the material. The process is straightforward, and it lends itself well to decompounding while being environmentally friendly. Its key function is cushion protecting and warmth reserving.

- Currently, it enjoys widespread popularity in modern batch production, particularly in the export packaging industry. It finds extensive use in various sectors like electronics, furniture, glassware, garments, and metal parts.

- Whoever aims at modern packaging and export, has to use PE foam for the following reasons: Packaging with air bubble film, EPS, and plastic film is forbidden in many countries.

- PE foam products have quite a few varieties: Sheets for direct wrapping and to make bags; PE sheets may be coated with plastic film, craft paper

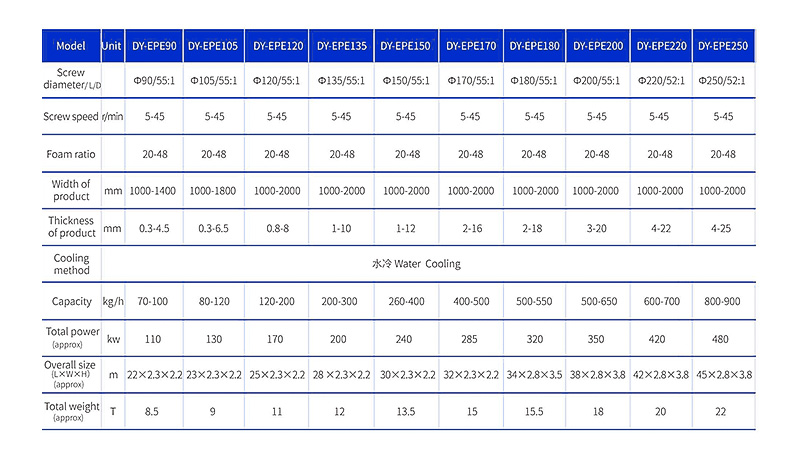

How many kinds of EPE Film Extruder does DEMENG COMPANY have?