Eps Foam Block Molding Machine Manufacturer Eps Block Moulding Production Line Plant

The introduction of eps block molding machine

The EPS block molding machine, also known as the eps block production line or EPS block molding plant, is a specialized piece of equipment used in the manufacturing process of Expanded Polystyrene (EPS) foam blocks. EPS foam is a lightweight and versatile material widely used in packaging, construction, and various other applications due to its excellent insulating properties and structural integrity.

Table of Contents

The process of eps foam block making machine

- Pre-expansion: The process begins with pre-expansion, where raw EPS beads are loaded into a pre-expander machine. The beads are exposed to steam, causing them to expand and become lighter. Pre-expansion is essential to reduce the density of the beads and make them suitable for molding.

- Curing: After pre-expansion, the expanded EPS beads are transferred to curing silos. The beads are left in the silos for a specific period, typically a few hours, to allow for complete evaporation of any remaining pentane, the blowing agent used during pre-expansion. This aging process ensures the stability and consistency of the expanded beads.

- Molding Chamber: The cured and expanded EPS beads are then fed into the molding chamber of the EPS block molding machine. The molding chamber is where the actual molding of EPS blocks takes place.

- Mold Cavity: The molding chamber contains a mold cavity, which determines the size and shape of the EPS blocks. The mold cavity is usually made of aluminum and can be customized to produce blocks of different sizes.

- Steam Injection: Once the molding chamber is filled with the expanded EPS beads, steam is injected into the chamber. The steam further expands the beads, causing them to fuse together and take the shape of the mold cavity.

- Cooling: After the steam molding process is complete, the steam is released, and the mold is cooled using air or water. The cooling process solidifies the EPS foam, and the blocks retain the shape of the mold cavity.

- Ejecting: Once the cooling is finished, the molded EPS foam blocks are ejected from the mold cavity, and the machine is ready for the next cycle.

- Cutting (Optional): Depending on the specific requirements, the large EPS foam blocks may be further processed by cutting machines to create sheets, panels, or custom shapes for various applications.

why choose us for eps block machine?

- Apply PLC controller and touch screen control system.

- Welded from high quality square profile steel and steel plate.

- Apply unique and advanced EPS heat penetration process.

- Advanced EPS heat penetration technique, reasonable pipeline system and unique design construction.

- Most of the main components are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.

- Apply hydraulic pressure transmission, hydraulic ingot stripping, which makes steady running and tight locking.

- High production efficiency. The production cycle of each plate is 4-8min.Automatic pneumatic charging shortening the production time.

- Apply high-efficient vacuum system and cooling device to improve moulding speed and reduce the moisture content. Vacuum supported machine is high efficient for making high-density thick

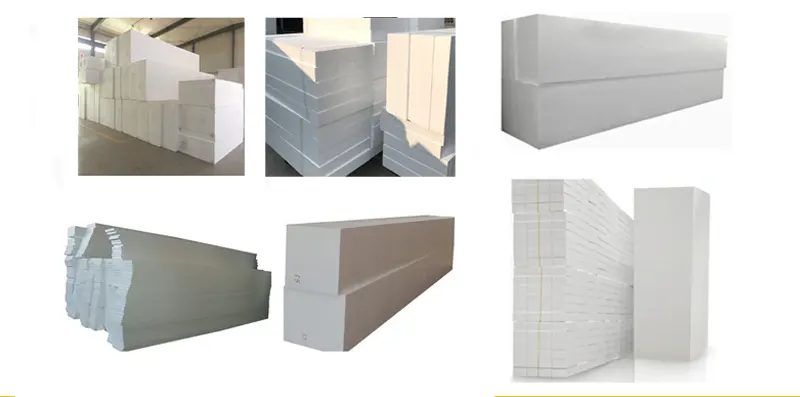

The usage of eps foam blocks

These blocks serve as the raw material for various EPS products, such as insulation panels, packaging materials, and construction components.